Stiffened panel buckling¶

Introduction¶

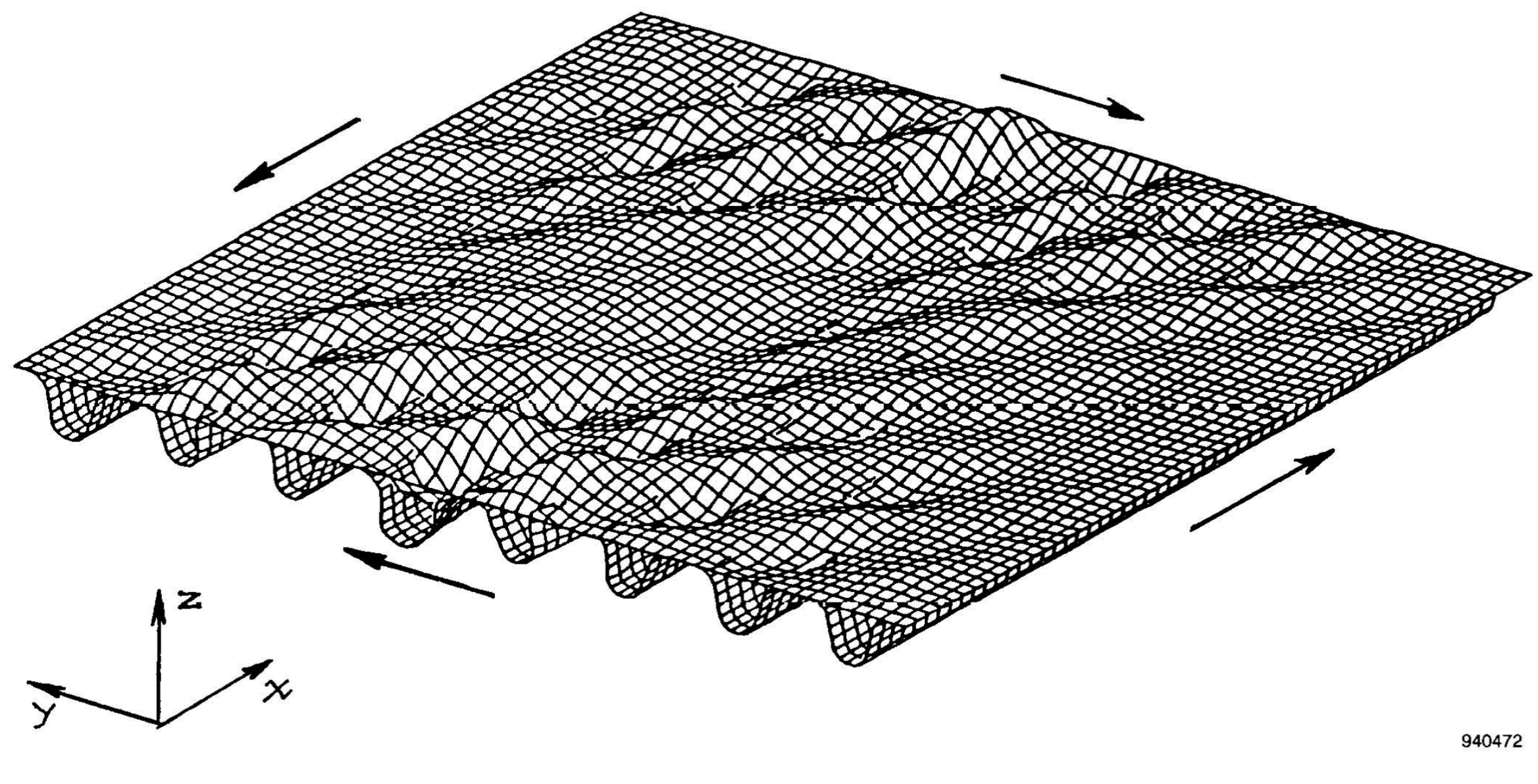

The following figure presents a stiffed panel subject to buckling on a military aircraft.

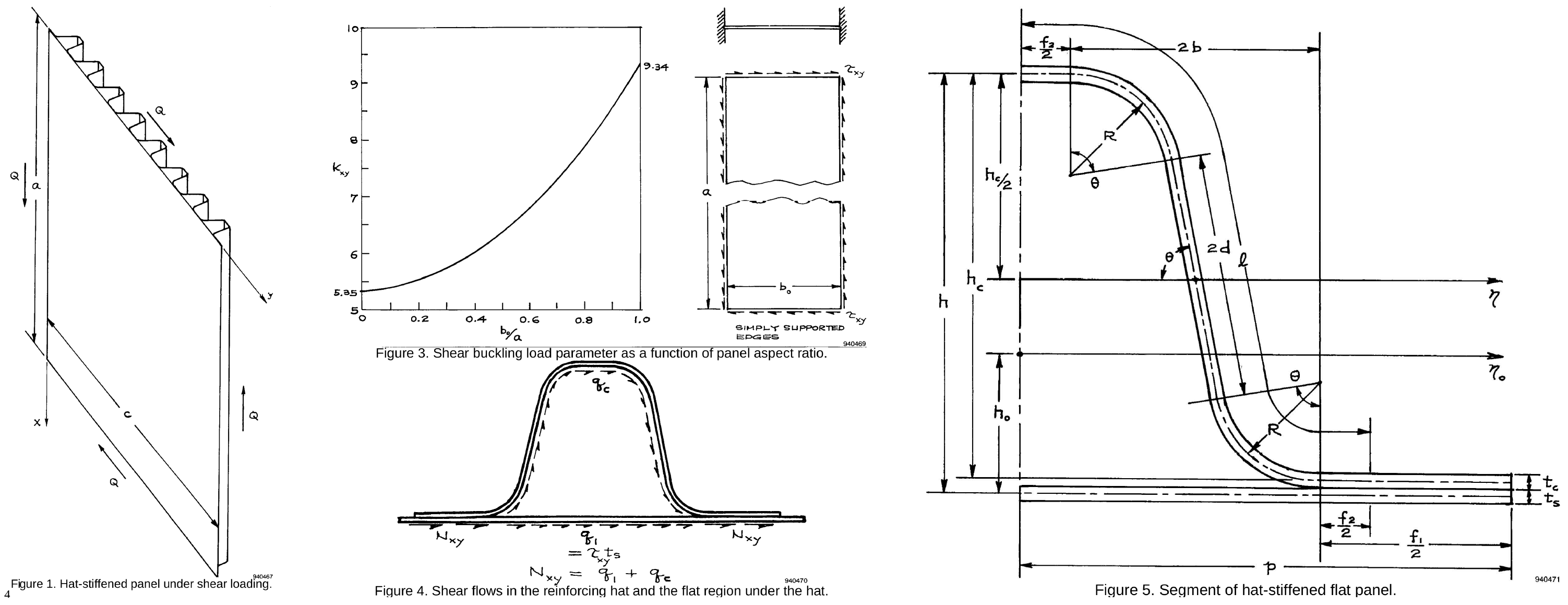

This use-case implements a simplified model of buckling for a stiffened panel (see [ko1994]).

Figure 1. Buckling of a stiffened panel.¶

Figure 2. 3D simulation of buckling.¶

Figure 3. Parameterization of the stiffened panel.¶

This test case is composed of ten random variables:

: Young modulus (

)

: Poisson coefficient (-)

: Distance between the mean surface of the hat and the foot of the Stiffener (

)

: Length of the stiffener side (

)

: Width of the stiffener foot (

)

: Width of the stiffener hat (

)

: Thickness of the panel and the stiffener (

)

: Width of the panel (

)

: Distance between two stiffeners (

)

: Half-width of the stiffener (

)

The output of interest is:

: the critical shear force (

)

We assume that the input variables are independent except the and

for which we measure a Spearman correlation of

,

modelled using a

NormalCopula.

The critical load of a stiffened panel subject to shear load is:

where:

is the width of the panel;

is the width between too consecutive stiffener feet;

is the thickness of the panel main surface;

is the Young modulus of the panel main surface;

is the Poisson coefficient of the panel main surface;

is the bending coefficient of the panel main surface:

is the load factor associated to shear buckling. It is given as a function of

through the empirical equation:

It is more convenient to use the shear force instead of the shear

stress component

. It leads to the equation:

where abd

are the shear fluxes in the panel main surface

and its stiffener. They are given by:

and:

where:

is the shear modulus of the panel main surface:

is the torsion strain of the panel main surface;

is the shear coefficient of the stiffener:

is the thickness of the stiffener;

is the distance between the mean surfaces of the stiffener hat and foot;

is the distance between the mean surfaces of the stiffener hat and the panel main surface:

is the width of the foot of the stiffener;

is the width of the hat of the stiffener;

is the half-widht of the stiffener;

is the radius of the circular part of the stiffener;

is the angle of the circular part of the stiffener;

is the length of the stiffener flank;

is the half-lenght of the straight part of the side of the stiffener;

is the area of the section of an half-ondulation;

is the area of the section of the full panel (main surface and stiffener) bounded by

:

is the distance between the mean surface of the panel main surface and the global geometric center of the panel:

It leads to:

and finally, is given by:

For industrial constraints, the stiffener and the main surface are cut in the

same metal sheet, so ,

,

.

The final expression of the critical shear force is then:

with:

;

;

;

.

References¶

Load the use case¶

We can load this model from the use cases module as follows :

>>> from openturns.usecases import stiffened_panel

>>> sp = stiffened_panel.StiffenedPanel()

>>> # Load the stiffened panel use case

>>> model = sp.model()

API documentation¶

- class StiffenedPanel

Data class for the stiffened panel model.

- Attributes:

- dimint

The dimension of the problem, dim=10

- model

SymbolicFunction Model of the critical shearing load. The model has input dimension 10 and output dimension 1. More precisely, we have

and

.

- E

TruncatedNormal Young modulus distribution (Pa), ot.TruncatedNormal(110.0e9, 55.0e9, 99.0e9, 121.0e9)

- nu

Uniform Poisson coefficient (-) distribution ot.Uniform(0.3675, 0.3825)

- h_c

Uniform Distance between the mean surface of the hat and the foot of the Stiffener (m) distribution ot.Uniform(0.0285, 0.0315)

- ell

Uniform Length of the stiffener flank (m) distribution ot.Uniform(0.04655, 0.05145)

- f_1

Uniform Width of the stiffener foot (m) distribution ot.Uniform(0.0266, 0.0294)

- f_2

Uniform Width of the stiffener hat (m) distribution ot.Uniform(0.00627, 0.00693)

- t

Uniform Thickness of the panel and the stiffener (m) distribution ot.Uniform(8.02e-5, 8.181e-5)

- a

Uniform Width of the panel (m) distribution ot.Uniform(0.6039, 0.6161)

- b_0

Uniform Distance between two stiffeners (m) distribution ot.Uniform(0.04455, 0.04545)

- p

Uniform Half-width of the stiffener (m) distribution ot.Uniform(0.03762, 0.03838)

- correlation_matrix

CorrelationMatrix The correlation matrix used for inputs dependence, mostly identity except for the term representing the interaction between variables

and

which is -0.8.

- copula

NormalCopula The (Normal) copula used to define the distribution of the input parameters.

- distribution

JointDistribution The joint distribution of the input parameters.

- independentDistribution

JointDistribution The joint distribution of the input parameters for the special case of independence.

Examples

>>> from openturns.usecases import stiffened_panel >>> # Load the stiffened panel model >>> panel = stiffened_panel.StiffenedPanel() >>> print("Inputs:", panel.model.getInputDescription()) Inputs: [E,nu,h_c,ell,f_1,f_2,t,a,b_0,p] >>> print("Outputs:", panel.model.getOutputDescription()) Outputs: [(N_{xy})_{cr}]

OpenTURNS

OpenTURNS